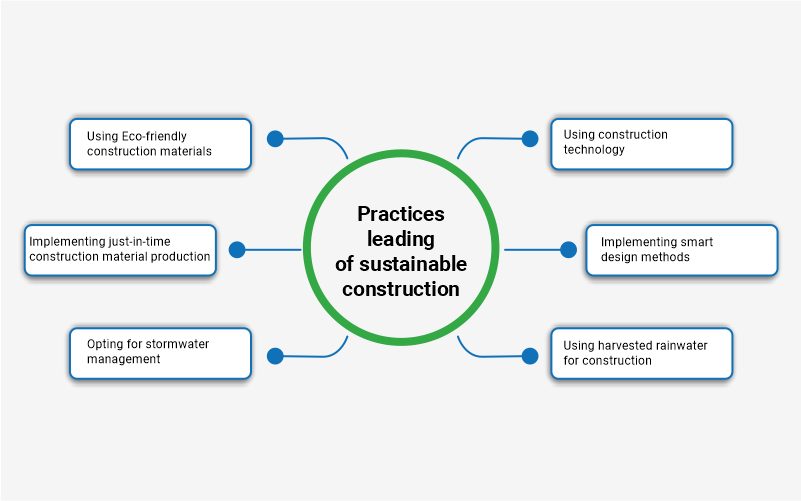

As more & more industries are embracing sustainability, the AEC industry has also begun to adopt sustainable construction practices. So, what is sustainable construction? Sustainable construction management refers to using sustainable construction procedures and sustainable building materials to reduce the carbon footprint and waste generation.

Sustainable construction requires leveraging environmentally responsible and resource-efficient processes throughout a building’s lifecycle from siting to design, construction, operation, maintenance, renovation, and deconstruction. Read on this Blog Post to learn the key best practices to achieve sustainable construction.

Smart Solutions for Net Zero Construction: Harnessing Technology’s Potential

Attaining net zero construction through technology solutions involves leveraging innovative technologies to achieve energy efficiency, renewable energy generation, and overall sustainability in the building industry. By integrating these solutions, we can significantly reduce carbon emissions and move closer to a net zero future. Here are a few key points on how technology can contribute to net zero construction:

Building automation and smart controls: Utilizing advanced automation systems and smart controls can optimize energy consumption by monitoring and adjusting lighting, HVAC, and other building systems based on occupancy and usage patterns.

Energy management systems: Implementing comprehensive energy management systems allows for real-time monitoring, analysis, and control of energy usage, identifying areas for improvement and optimizing energy efficiency.

Renewable energy generation: Embracing technologies such as solar panels, wind turbines, and geothermal systems enables on-site renewable energy generation, reducing reliance on fossil fuel-based grid electricity.

Building-integrated photovoltaics (BIPV): Integrating solar panels directly into building elements, such as windows, facades, or roofs, combines energy generation with architectural design, maximizing the use of available space.

Energy storage solutions: Implementing energy storage systems, such as batteries, allows for the capture and storage of excess renewable energy generated, ensuring a continuous power supply even during periods of low generation.

Building information modeling (BIM): BIM technology enables the creation of digital models for efficient design, construction, and operation of buildings, optimizing energy performance, and minimizing waste.

Internet of Things (IoT): IoT devices and sensors can be used to monitor and optimize energy consumption, occupancy patterns, and indoor environmental quality, leading to energy-efficient and comfortable buildings.

Green building materials: Advanced materials with improved insulation properties, lower embodied carbon, and increased durability can contribute to energy efficiency and sustainability in construction.

Digital energy platforms: Integrated platforms that combine energy management, data analytics, and renewable energy procurement enable efficient energy use, demand response, and the integration of renewable energy sources.

By embracing these technology solutions, net zero construction becomes more attainable, enabling the creation of sustainable, energy-efficient, and environmentally conscious buildings.

Using Alternative Construction Materials

The construction industry generates several tons of construction waste in debris, building blocks, concrete, wood and asphalt collection.

Overtime period accumulation of these wastes causes soil, water and air pollution. To reduce the amount of waste generated by the construction industry, the concept of sustainable construction is gaining momentum. To attain sustainable construction goals, pollution-created resources are required to be replaced with eco-friendly materials.

Concrete forms 70-80% of the structure in building projects, and replacing it with eco-friendly alternatives can go a long way in achieving sustainability objectives. Also, concrete structure demolition leads to a massive wastage generated across the world. Moreover, to build a project from scratch, the builders need to obtain raw materials from the earth, further depleting the renewable resources. To curb these challenges, the adoption of green building materials can be an effective & viable solution. So replacing concrete with bamboo, recycled plastic, ferroc and hempcrete, is a significant move towards sustainable construction.

To minimize the pressure exerted on natural resources because of construction activities, the AEC organizations need to find recyclable alternatives to conventional construction materials. At the same time, the industry can reduce demolition pollution by recycling products like doors, windows, structures instead of disposing of them. Today’s construction firms can utilize recycled doors, panels, and structures for future projects & help in making the world a better place. Recycling and reusing not just reduce pollution but also effectively contributes to cost-savings.

Implementing “Just-In-Time” Construction Material Production

The construction companies often order a surplus amount of construction material for their projects. The number of materials purchased most of the time is way more than the required quantity. The additional purchase contributes to excessive waste generation.

Instead of reselling the surplus materials, the construction companies simply dump them in the warehouses in light of using them for future projects. However, most of the time due to project delays or failures, the dumped material deteriorates in the warehouse & becomes unworthy of future use. Construction materials such as wooden planks become damp and metal materials become rusted due to prolonged exposure to sun, rain and air. The damp and rotten materials lose their durability and lifespan, thus becoming useless waste.

To counter this challenge, modern manufacturers are embracing just-in-time production. Here the contractors receive only a specific amount of materials on a set date. This also means that the contractors cannot reorder the materials till the previous batch of materials has been utilized. This process helps the manufacturers to limit material production and reduce the waste generated. The process is eco-friendly as no surplus material is produced, and every material is utilized. The process helps the construction companies to reduce the cost spent on storing materials, free up storage space and contribute to the conservation of natural resources.

Practicing Alternative Construction Methods

Construction companies need to adopt alternative construction methods to attain sustainability goals. One effective alternative construction method involves off-site assembling of the structure through 3D modeling, sketches and structure models. The improvisations in the project can be done easily in 3D models through BIM technology (Building Information Modeling), and then the finalized project model is delivered to the project site for construction. Several construction firms create the base structure in the warehouses first and then transport it to the site.

To facilitate this practice, assembly factories and warehouses must be equipped with necessary tools, machinery and equipment. As a result, the pre-structure construction saves time and money on onsite construction. This way, the onsite team saves time and energy invested in constructing the building structure. The process is also known as prefabricating construction, and it saves 70% of the energy invested in building a conventional structure. Furthermore, prefabricating materials in a controlled environment contribute to a stronger building base.< A common instance is mechanical contractors using BIM to cut sheet metals required for ductwork in a controlled environment instead of doing it onsite. Onsite sheet cutting creates shape-changing problems due to exposure to climatic conditions. Prefab structures reduce construction time and energy and reduce the waste produced.

Smart Designing Methods and Considerations

Instead of using outdated, manual & legacy construction methods, construction companies need to go for smart designing ways. Modern-day builders choose advanced construction software to design 3D models sketches. The software offers easy rework solutions and also proactively reduces the construction waste generated. Investing in a dynamic Construction ERP saves time, money and also storage space. Today’s innovative construction tools enable cross-platform sharing of design ideas. Moreover, the cloud-based storage of invoices, documents and contracts also helps to eliminate the communication conflicts between contractors, subcontractors, investors and builders. The digital transformation has brought many benefits that also have a positive impact on the fight against climate change and reduce CO₂ emissions.

The cutting-edge software tools also help check machine faults & effectively manage material purchase and supply, thus reducing the pollution caused by unnecessary transportation & replacement transits. Also, the smart designing approaches offered by such solutions help to bring more sustainability to the construction projects. Moreover, it helps to improve collaboration between the various stakeholders helping to effectively conduct off-site manufacturing towards more sustainable construction. Smart designing methods can improve the efficiency of the construction and manufacturing processes by more than 40%.

Use of harvested rainwater during construction

Water, a natural resource, is abundantly used in construction projects. Water is used for cement mixing, preparation of molds, plastering, watering building and cleaning. However, water scarcity impacts the construction process and can slow down work. But rainwater harvesting can be a great solution to counter these challenges. Rainwater harvesting implies capturing and storing rainwater for future use and eliminating water security issues. In the construction process, rainwater harvesting is used for cooling towers, fire suppression, manufacturing, vehicle processes & pool fills.

The primary benefits of rainwater harvesting include:

Stormwater management

Rainwater harvesting helps in achieving stormwater compliance.

Reduced cost

The stormwater regulations call for the usage of retention ponds to meet the mandatory standards. However, the cost of constructing retention ponds is high and also uses large spaces. Rainwater harvesting helps reduce the cost of building the retention posts and also helps to repurpose the pond space.

Easy irrigation

In large-scale projects, gallons of water are utilized every year. Rainwater usage considerably reduces the cost spent on irrigation and getting a huge water supply.

LEED points

Opting for rainwater harvesting makes a construction project eligible for achieving LEED points and mitigation credits.

Fire extinguishing

A construction project needs to store a thousand gallons of water for fire safety. Rainwater harvesting helps store hundreds of thousands of gallons of water for any unprecedented fire extinguishing process.

High water quality

Water from ponds and underground has a high amount of dissolved solids. However, rainwater is naturally soft has a low amount of dissolved solids. Therefore, rainwater requires minimal filtration to be easily used for a wide range of construction processes.

Stewardship

Rainwater harvesting helps to limit groundwater usage. Thus, it helps prevent the depletion of water resources and reduces the carbon footprint on centralized waters.

Sustainable construction focuses on six principles: “conserve, reuse, recycle/renew, protect nature, create non-toxic and high quality.” The objective is to minimize the industry’s impact on the environment by applying sustainable development practices, employing energy efficiency, and leveraging green technology. The adoption of eco-friendly practices & tools will benefit the construction firms in the long run and significantly help conserve the environment & fast-depleting resources.

About Author

Olivia Jones

Technology Specialist

Olivia is a highly skilled and experienced Technology Specialist with 10+ years of hands-on expertise in the rapidly evolving field of technology. She has a proven track record of successfully implementing and managing a wide range of technological solutions, ensuring optimal performance and efficiency. Olivia possesses a deep understanding of industry trends and emerging technologies, enabling her to provide strategic guidance and drive innovation within organizations. With a strong focus on problem-solving, she consistently delivers tailored solutions that align with business objectives while maximizing productivity and cost-effectiveness.

About SoftTech Engineers

A leading IT company (www.softtech-engr.com) facilitating business and technology transformation across the AEC industry through innovative software products and solutions. Equipped with 25+ years of deep domain expertise and industry knowledge, SoftTech has helped more than 4500 clients & government organizations, with more than 25000 users in India and around the world to gain a competitive edge and lead from the front in the industry.